Intelligent warehouses based on the IoT

Sales growth in e-commerce is good. But as the business expands, it becomes increasingly difficult for warehouse managers to track large volumes of goods. Products can get lost, deteriorate or, conversely, take up extra space. In order to restore order and have time to respond to customer requests on demand, warehouses turn to IoT devices. Let’s look at how the Internet of Things simplifies inventory control and revolutionizes warehouse management.

Inventory management means coordinating and controlling the movement of goods in a warehouse:

- getting new products;

- their movements around the warehouse;

- storage of products;

- return of units;

- SKU extension;

- checking the rack code, and so on.

It is often impossible to fit such volumes of information into spreadsheets. Besides, it is not very convenient. Therefore, enterprises buy IoT solutions for warehouse management in order to work efficiently.

IoT solutions for enterprises

IoT devices automate warehouse processes and reduce labor costs. This can be done by implementing the following technologies:

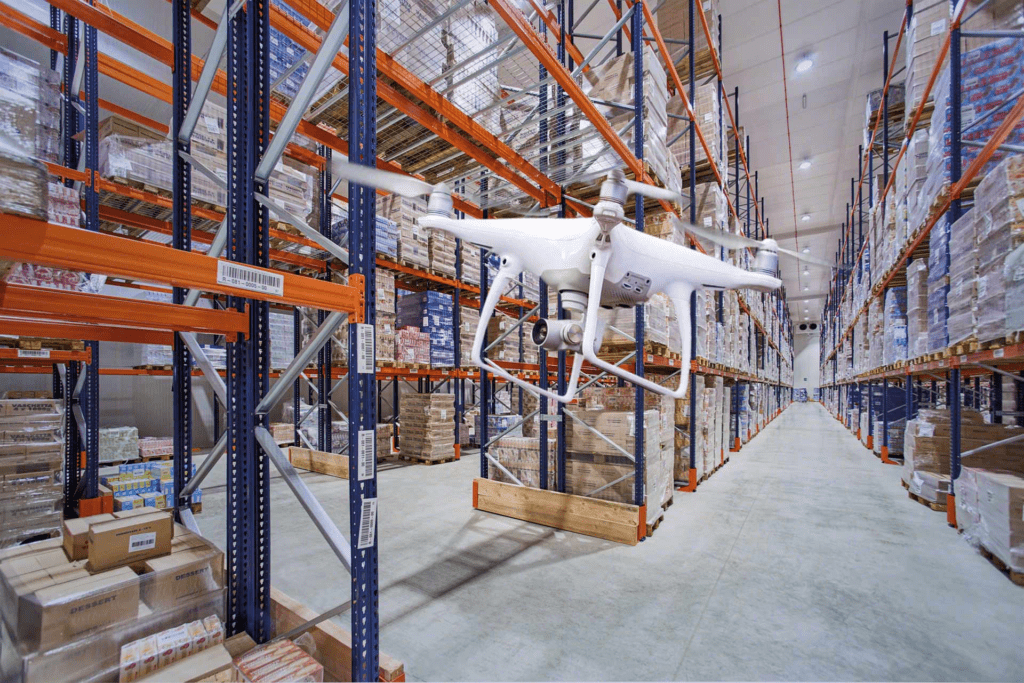

Drones

It is not easy to move around a large warehouse to describe the location of goods and climb the stairs to high shelves. In addition, it takes a lot of time to search.

Drones, as part of the IoT, can do this job faster by instantly scanning goods in any corner of the warehouse and at any height. They don’t stop doing it even at night.

Robots

Industry and warehouses are priority places where global robotization is unfolding. According to recent reports, the warehouse robotics market is steadily by 15.26% per year and will reach $9.5 million by 2026.

Amazon has long had an army of 200,000 robots working in warehouses with humans. They saved people from having to walk 10-20 miles a day on a concrete floor and helped the company store 40% more inventory. They also increased the average productivity of the assembler to 100 units per day, and managers plan to increase these figures by 3-4 times.

Radiofrequency identification tags

Radio Frequency Identification (RFID) tags can be embedded in IoT devices. These tags store much more data than traditional barcodes. They can be used to scan up to 200 tags at a time.

The received inventory information is stored in the cloud platform, automatically processed, and analyzed. The expiration date, serial numbers, sizes, manufacturers, and other product information do not need to be entered manually on the panel.

Voice selection systems

Warehouse workers can use IoT devices to increase the efficiency of operations. For example, voice systems allow you to work without the help of hands, giving instructions and directing workers through their list of orders.

Sensors

Connected devices are able to track the productivity of warehouse workers using speed, motion, and GPS sensors. Managers also better control the goods in the warehouse by measuring humidity, temperature, and other characteristics that can spoil the products.

DHL has similar innovations in its warehouses. The company uses smart glasses, robots, drones, a digital twin, and other technologies. The IoT increases warehouse security, tracks the location of goods, and predicts weather changes and possible equipment failures or breakdowns. Up to the point that the warehousing of goods begins 30 minutes after receipt, and outgoing goods are ready for shipment in 95 minutes.

Problems that IoT solves

The main problem of warehouse management is manual work. Working with their hands, employees perform operations more slowly, with a higher probability of errors and damage to inventory. IoT solutions for enterprises simplify the following management and work tasks:

Product search

Imagine that the manager has a warehouse of several floors at his/her disposal. How to track where a particular product is located? Or how to avoid a situation when an employee wants to pick up a product from the right place, but it is not there?

You will have to spend time correcting errors and searching for the goods, which will delay the shipment. To avoid such problems, it is worth using IoT and the best warehouse management system, which automates registration and data tracking.

Movement of goods

Any movement of the goods must be recorded by the manager. At the same time, he/she needs to know how many units are arriving and how many are leaving. It’s hard to keep track of the exact numbers, but with IoT solutions for business, it becomes easier. Thus, reporting will not be such a difficult task. In addition, connected device analytics will tell you which products will increase demand in the near future.

Use of storage areas

In the warehouse business, it is important not only to accept goods but also to place them efficiently. Then it will be convenient for employees to pick up goods from the shelves, and they will do their job without delay. If you configure the storage system manually, you can repeatedly make mistakes and redo the layout. With IoT, this is done quickly and with minimal effort.

Warehouse equipment maintenance

Any equipment breakdown can lead to downtime, which distributors do not like. IoT devices for enterprises are able to monitor the status of equipment and warn about possible failures. Thus, managers will be able to prepare spare equipment in advance, avoid downtime, save money, and preserve their reputation.

Storage of goods

It is extremely important that during the storage period in the warehouse and during its delivery to consumers, the goods do not deteriorate. According to the latest data, about 11% of products die during transportation due to the fact that managers did not provide proper conditions for their storage.

It is necessary to maintain the desired temperature and humidity so that the product can be brought to the endpoint and sold. IoT devices are able to control environmental parameters, saving goods from deterioration.

Advantages of using IoT

And now, let’s take a deeper look at the advantages of the Internet of Things, supporting them with figures.

Saving on salaries

An average warehouse with a hundred employees can allocate about for wages. This amount is approximately 65% of the operating budget.

With the help of the IoT, employees sort goods on shelves faster; in addition, they search for goods, check equipment and perform other tasks more efficiently. Automation brings great money savings.

Better use of the warehouse

The average warehouse area is 16,400 feet. This is a huge space where you need to conveniently and appropriately arrange products. However, overloading and improper distribution of goods can lead to traffic jams and delays on the roads.

You have to move inventory or take it out, which takes time and labor.

With the help of the IoT, you can place more goods in the same area so that it is convenient to find empty seats and later fill them with new goods. Automated storage and search systems are able to increase the accuracy of orders by up to 99%. Taking into account the fact that rents are growing and will not stop growing in the future, rational use of space is a matter of saving and making a profit.

Information support

The number of goods is , and slow goods are taking the place of strategically important products. Less relevant products stay in stock longer and require placement, which increases the rental cost.

Not all warehouses have an adequate information support system. In other words, managers have no idea what the supply and demand in the market are. IoT analytics provides information about the state of the market so that managers can rationally manage purchases and plan other operations based on inventory.

IoT devices for enterprises give managers the opportunity to cover large warehouse work, put it in order, automate, and speed up.

Andersen will help implement the and automate important operations. If you are ready to save time and resources with the help of new digital technologies, contact our team for a private consultation.